IR cameras

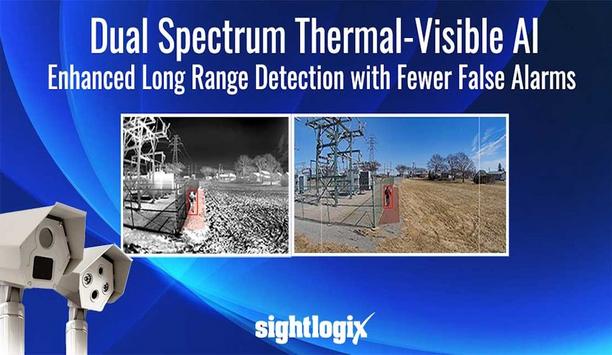

SightLogix, a pioneer in intelligent outdoor security solutions, has announced dual-spectrum AI for its dual-sensor SightSensor product series. This new capability integrates thermal and visible AI validation, providing unmatched, real-time intrusion detection that minimises false alarms. Reliable and immediate awareness is mandatory for high-performing perimeter security solutions in critical infrastructure and commercial remote video monitoring applications. Edge-based intelligence Th...

Motorola Solutions announced the new Pelco, an innovative portfolio of artificial-intelligence-powered devices that are purpose-built for enterprises operating in some of the most challenging environments, like oil and gas and ports. Backed by the company’s deep engineering expertise and significant investments in research and development. Smart surveillance The portfolio brings together specialised security technologies from the strategic acquisitions of VideotecPelco’s dev...

At ISC West 2025, April 2-4, in booth 11053, Bosch will demonstrate artificial intelligence-enabled video solutions that empower proactive responses to improve security and safety for customers. An expanded Intelligent Video Analytics Pro (IVA Pro) suite, now including 12 Licence, uses deep neural network-based video analytics for accurate, precise, and reliable detections, alerts, and data capture. Introducing the next level in visual intelligence, Bosch will also preview IVA Pro Context, a s...

Teledyne FLIR OEM, part of Teledyne Technologies Incorporated, announced Prism™ SKR, the newest addition to the Prism embedded software ecosystem. Prism SKR, pronounced “seeker,” sets a new standard in precision automatic target recognition (ATR) for autonomously guided weapon systems, including loitering munitions, air-launched effects (ALE), counter-unmanned aerial systems (C-UAS), low-cost missiles, and smart munitions. Prism SKR's advanced algorithms Prism SKR operates s...

Quanergy Solutions, Inc., a global pioneer in high-performance LiDAR-based security and smart space solutions, announces a technology partnership with Netsocs. An integration and automation software solution provider specialising in electronic security. Smart security with LiDAR Netsocs’s versatile and powerful management platform helps to deliver unparalleled operational intelligenceThe partnership combines invaluable data from Quanergy 3D LiDAR sensors with Netsocs’ highly...

FLIR, an industry pioneer in visible and thermal imaging sensors for security applications, will use ICS West 2025 to show visitors how they can benefit from adopting a multi-layered approach to their security challenges. With extensive experience across applications that include fence line/perimeter protection, parking lots, outdoor area protection, and entry/interior area protection, FLIR designs its solutions as building blocks that can integrate to form a robust multi-layered security solut...

News

Data centre maintenance teams have a big share in safeguarding the critical resource that customers and businesses depend upon. Fortunately, they have one secret weapon that enables them to spot issues in an early stage before they turn into big problems: FLIR thermal imaging. The data centre market has seen a massive growth in recent years. Spurred by a growing adoption of cloud technologies, AI, IoT, 5G and big data, new data centres are being built across all continents at fast pace. Whether they are in-house data centres for some of the largest and most influential companies, or built by specialised vendors offering infrastructure services, data centres fulfill a critical role in maintaining the continuity of a business. Downtime of a data centre Guaranteeing uptime has become increasingly complex for data centres Downtime of a data centre can have an enormous economic impact and needs to be avoided at all costs. In addition to financial loss, reputational damage can be equally impactful, especially when the data centre is supporting customer-facing services. Guaranteeing uptime has become increasingly complex for data centres. With so much mechanical, electrical and electronic infrastructure under one roof, overheating is a major concern, not only because the infrastructure is not using the energy efficiently, but also because overheating can cause a complete shutdown of servers, impacting users around the world, or even data or equipment loss. One of the most reported incidents is the 2013 overheating of a Microsoft data centre operating some of its cloud services, including Outlook, which led to services being lost for 16 hours. Maintenance inspections with thermal imaging cameras The maintenance of a data centre today involves much more than IT operations. Power distribution systems and cooling infrastructure are also essential for keeping the data centre up and running, and for preventing mechanical or electrical failures and resulting outages. Many systems that are critical for the data centre’s operation heat up before they fail. Temperature is an important indicator of energy consumption and equipment operation, which is why infrared thermography (thermal imaging) is an ideal tool to inspect power consumption, electrical installations, cooling equipment and computing hardware. Periodic inspections with thermal imaging camera Thermal cameras help maintenance staff to detect problems in electrical switchgear, motors Periodic inspections with a thermal imaging camera have become indispensable in predictive and preventive maintenance programs. Thermal cameras help maintenance staff to detect problems in electrical switchgear, motors, HVAC infrastructure, uninterruptible power supplies (UPS), power distribution units (PDU), batteries and generator equipment and all electrical devices that feed the server systems, before these problems turn into serious failures or downtime. Rise of cloud computing With cloud computing becoming the new normal, and as data centres are growing to great scales, the need for higher computing density and power efficiency is growing as well. Data centre owners are seeking ways to increase their capacity, but they also want to reduce costs and energy. Thermal imaging can give them important information on how to optimise energy and space requirements, without causing overheating. In short, regular inspections with thermal imaging cameras can help maintenance staff to: Find and fix hidden problems before they turn into unplanned downtime. Reduce the chance of component degradation going unnoticed due to overloaded circuits or loose connections. Prevent equipment breakdowns. Optimise energy management and space allocation. What is Thermal Imaging? A thermal camera is a non-contact device that detects infrared energy (heat) A thermal camera is a non-contact device that detects infrared energy (heat) and converts it into a visual image. Infrared radiation lies between the visible and microwave portions of the electromagnetic spectrum. Any object that has a temperature above absolute zero (-273.15 degrees Celsius or 0 Kelvin) emits radiation in the infrared region. Even objects that are very cold, such as ice cubes, emit infrared radiation. Thermal cameras turn this invisible energy into something that can be seen on a screen and measured. The Benefit of Thermal Imaging Why to choose a FLIR thermal imaging camera? Sure, there are other technologies available to help measure temperatures – infrared thermometers or thermocouples to name only two. But no other tool is as powerful and efficient as a FLIR thermal imaging camera. See the whole picture Unlike IR thermometers or thermocouples, thermal imaging cameras enable to scan large areas for hot spots or temperature differences. Without a thermal camera, it’s easy to miss critical parts like air leakages, areas with insufficient insulation or water intrusion. A thermal imaging camera can scan entire electrical installations, buildings A thermal imaging camera can scan entire electrical installations, buildings, heating or HVAC installations. It never misses a potential problem area no matter how small this might be. They also allow to compare temperatures of components in the same environment more easily. Save time and costs Maintenance of data centre installations can be labour-intensive. Because they can easily see larger surfaces, thermal imaging cameras can be the solution to reduce maintenance time speed up inspection rounds, and still see all impending failures, before they turn into costly defects. Inspect without shutting down Thermal imaging is a non-contact technology. This is a safe method, because maintenance personnel can keep a distance without having to touch hot items. But it also means that inspections can easily be carried out while the equipment is still running or under load. There’s no need to foresee costly downtime. Some inspections, for example rotary UPS systems, can only be done during operation, which makes the thermal imaging camera an ideal tool for online inspections. Report Like a Pro Users can compare current inspections with historical data and discover trends Thermal imaging cameras allow users to make professional, more insightful reports of their inspections that also look great for management and customers. Users can compare current inspections with historical data and discover trends. Features like templates, batch processing, image editing and route planning further enhance the use-friendliness of today’s reporting solutions. Thermal imaging applications Thermal imaging is the perfect technology to tackle the wide range of maintenance and inspection jobs for data centres. Electrical and Mechanical Systems Thermal imaging cameras can be used to inspect a variety of electrical or power generation-related systems. Heat is an important indicator for defects in electrical installations. When current passes through a resistive element, it generates heat. Over time, the resistance of electrical connections can increase, due to loosening and corrosion for instance. The corresponding rise in temperature can cause components to fail, resulting in unplanned outages. Electrical systems can also suffer from load imbalances and increases in impedance to current. Thermal inspections can quickly locate hot spots, determine the severity of the problem, and help establish the time frame in which the equipment should be repaired. Thermal imaging cameras will help you to spot issues with: Overheated connections Overloaded or imbalanced circuits Damaged switches Faulty fuses Power supplies Battery systems Generator systems Uninterruptible Power Supplies (UPS) Transformers Electrical panels Resistive load banks HVAC and Cooling Systems To run smoothly and efficiently, data centres need perfectly air-cooled conditions To run smoothly and efficiently, data centres need perfectly air-cooled conditions. Data centres are typically making use of a hot aisle/cold aisle layout principle. Server racks are lined up in aisles with the front sides facing each other. The cold aisles get cold air directly from the Computer Room Air-Conditioning (CRAC) unit from the bottom of the raised floor. The cool air cools down the servers on the racks. Meanwhile, the backs of the servers vent out hot air in the hot aisle, which then returns to the CRAC unit. Thermal imaging has become increasingly important to verify the proper hot aisle/cold aisle operation, especially because data centres today are condensing more servers into their racks. Thermal cameras will enable users to see problems such as misaligned ductwork and electrical faults, and then make decisions about corrective actions. HVAC inspection with a thermal imaging camera can help to: Monitor server rack temperature distribution patterns Locate misrouted and leaking ducts See electrical or mechanical CRAC unit defects Confirm the source of energy losses Find missing insulation Discover AC condensate leaks Find internal server fans which are inoperable or damaged Renewable Energy Data centre operators are increasingly improving their use of renewable energy sources Data centre operators are increasingly improving their use of renewable energy sources, including solar and wind power. These renewable power sources enable data centres to reduce their environmental impact, while meeting long-term sustainability goals. Solar Power The solar panel, the most important part of a solar system, must be reliable and capable of producing electricity for years on end. Unfortunately, solar panels are susceptible to wear. Maintenance professionals therefore use thermal imagers to inspect solar panels installed on rooftops or in solar parks to quickly pinpoint solar panel problems down to cell level. Anomalies can clearly be seen on a crisp thermal image and - unlike most other methods - thermal imaging cameras can be used to scan installed solar panels during normal operation. Thermal imaging cameras also allow users to scan large areas within a short time frame. Wind Power Wind turbine components are susceptible to wear and can break down. That’s why preventive maintenance and periodic inspections are so important. Thermal imaging is the only technology that allows users to inspect all electrical and mechanical components of the wind turbine and the surrounding electrical system, so they can detect a problem before a breakdown occurs. Fire Protection Although data centre fires are relatively rare, they can have a devastating impact Although data centre fires are relatively rare, they can have a devastating impact. Data centres may be equipped with fire alarms and firefighting systems, but once a fire starts, asset damage is almost certain. Fixed thermal imaging cameras can identify hot spots before they ignite and provide an early warning response to avoid a full-on destructive fire before assets are harmed or safety is compromised. Physical Security Thermal cameras not only detect hot spots or temperature differences. They also help protect a physical perimeter against unwanted intruders or trespassers. As data centres operate 24/7, they need effective solutions to help them monitor the premises and detect threats around the clock. Thermal security cameras that offer high contrast, high resolution and long detection ranges are ideal for data centre deployments. 4/5 Unlike standard video cameras, thermal cameras can see in most adverse weather conditions– such as light rain, fog, smoke, or total darkness. When integrated with video analytics, thermal cameras can distinguish between a human or vehicle. When paired with radar, customers gain redundancy and reduce the likelihood of a false positive. By combining thermal cameras with HD visible cameras, remote operators can review thermal and visible video streams of the scene for improved alarm verification and intruder identification. Thermal Imaging Solutions from Teledyne FLIR Handheld thermography cameras FLIR thermography cameras always offer the highest accuracy and user-friendliness Armed with a FLIR thermal imaging camera, maintenance crews can easily diagnose a wide range of problems across their data centre facility. Available in a wide variety of sizes and image resolutions, FLIR thermography cameras always offer the highest accuracy and user-friendliness to meet the needs of maintenance professionals. Thermal Studio Software with Route Creator FLIR Thermal Studio Suite is state-of-the-art analysis and reporting software designed to help data centre maintenance teams manage thousands of thermal images and videos. Whether using handheld thermal cameras or unmanned aircraft systems (UAS), the FLIR Thermal Studio suite of software provides the automation and processing capabilities needed to streamline workflow and increase productivity. The optional Route Creator plugin allows users to plan inspection routes in advance, complete inspections more efficiently and reduce reporting time by 50%. FLIR CARE’s traceable calibration services Keep the thermal camera in optimal performance condition and avoid unforeseen downtime with a FLIR CARE service package. Whether looking for a performance verification service or a traceable calibration adjustment service, FLIR CARE’s traceable calibration services have covered everything. FLIR PROTECT Service Packages FLIR PROTECT Extended Warranty and Service Packages give the peace of mind that the camera is protected from material defects and issues for three years after the factory warranty expires. Choose FLIR Protect+, FLIR Protect Pro, or FLIR Total Protect to bundle a discounted FLIR CARE Service with the FLIR PROTECT extended warranty.

Brady Corporation offers a new, more cost-efficient solution to quickly detect unstable Li-ion batteries in storage. Able to automatically measure 0,5°C temperature differences per second, the solution provides the accuracy and speed needed to isolate unstable batteries before they become a safety risk. Brady’s new battery temperature monitoring solution involves three components: self-adhesive battery-free UHF RFID labels with embedded temperature sensors, RFID readers with up to 16 antennas, and a customisable RFID software platform. RFID software platform RFID antennas and readers automatically power all labels and sensors in range to pile temperature readings The self-adhesive UHF RFID-embedded labels can be applied inside battery cell boxes for fast temperature change detection. Alternatively, every battery cell can be labelled with Brady’s on-metal, printable UHF RFID labels to enable more elaborate advantages in Li-ion battery supply chains. Every second, the RFID antennas and readers automatically power all labels and sensors in range to collect temperature readings with 0.5°C accuracy. Every temperature reading, and matching battery storage location, is collected by the RFID software platform. When customisable temperature thresholds are reached, the software platform triggers third-party devices via standard API. Brady’s software platform API With almost continuous, automated and accurate temperature monitoring, warehouse stakeholders can receive early warnings via sms, email or even racking warning lights. They can be guided in time to specific warehouse locations for unstable Li-ion battery isolation. Alternatively, Brady’s software platform API can also trigger an autonomous vehicle to automatically remove an unstable battery. RFID tags or IR cameras Battery-free UHF RFID labels with embedded sensors are a more cost-effective battery temperature monitoring solution than powered RFID tags or IR cameras. UHF RFID labels and their temperature sensors receive power wirelessly from RFID antennas and readers in range. They are available at significantly lower costs - up to five times less than battery-powered RFID tags-and do not require maintenance. Temperature monitoring solution Brady connects up to 16 antennas to a single RFID reader that provides high accuracy and high-speed The number of RFID readers needed to completely cover storage locations in a warehouse heavily depends on warehouse setup, racking height and storage volume per racking compartment. Brady can connect up to 16 antennas to a single RFID reader that provides high accuracy, high-speed temperature monitoring for all storage locations in 12-metre-wide and 4-metre high racking. The automated, and almost continuous, nature of the temperature monitoring solution enables Li-ion battery manufacturers and logistics companies to significantly increase safety and reduce risk at advantageous costs. Brady’s RFID readers By adding an RFID reader gate at designated warehouse exits, Brady’s solution can also enable automated, real-time warehouse inventories. RFID labelled items are read by Brady’s RFID readers the moment their label enters reader range. When they pass through a designated RFID reader gate, these items can easily be subtracted from the inventory by the RFID software platform. When used in this way, the solution can provide cost-effective battery track & trace inside the warehouse from entry to exit, complete with battery cell box or battery cell temperature fluctuation in between.

Industrial Video Solutions Inc (IVS), a US-based specialist in automation for the papermaking industry, is leveraging FLIR infrared (IR) thermal cameras to obtain valuable data from paper machines as part of a patented system that boosts machine control and efficiency. Moisture and temperature directly affect both paper properties and machine runnability making the measurement of these parameters essential to the papermaking process. However, despite the presence of visual spectrum cameras in several machine locations, some aspects of the papermaking process remain invisible to operators. This problem is attributable to factors such as steamy operating environments, visual camera limitations, and a lack of tools that convert camera images into actionable data. IVS-patented system With its FLIR cameras, ThermoVision sees real-time moisture profiles in any paper machine location The solution arrives in the shape of ThermoVision, an IVS-patented system featuring FLIR IR cameras at its core. With its FLIR cameras, ThermoVision sees real-time moisture profiles in any paper machine location, mapping them to a multi-functional thermal profiler. The system can provide real-time, full-width, cross-direction (CD) moisture and temperature profiles, as well as real-time machine direction (MD) profile variations. Moreover, profile analytics provide insights into dewatering and drying efficiency - critical for energy benchmarking. Real-time detection ThermoVision facilitates the real-time detection and classification of wet streaks and spots, as well as the real-time detection of embedded foreign materials, such as metals in fluff pulp. A key capability of the system is its ability to provide visibility in steamy machine locations. Using a FLIR IR camera to capture an image of a pulper vortex, for example, allows users to see through the steam and visualise the vortex in full detail, including the position of the chain and vortex edges. This ability is indispensable for monitoring locations within the machine like trim squirts and dryers. IR and visual spectrum cameras It is even possible to feed data from a combination of IR and visual spectrum cameras to an AI module While it only requires a single FLIR IR camera to execute all ThermoVision analyses, multi-camera systems are more effective for complete process troubleshooting, optimisation, and improvement. It is even possible to feed data from a combination of IR and visual spectrum cameras to an artificial intelligence (AI) module. This neural network learns the relationship between the forces exerted on the paper, paper vulnerabilities, and process upsets - such as sheet breaks - with the goal of predicting runnability issues. Seven-figure savings “Armed with new data for maximising paper machine performance, we estimate substantial savings for ThermoVision users,” says Slawek Frackowiak, President and CEO of IVS. “For example, reductions in energy consumption and paper breaks, alongside increases in productivity, can lead to annual savings in the region of $1.3 million on a 300,000-ton liner-board machine.” He continues: “We came across the potential for this technology by chance. We had already patented our ProcessVision technology, which extracts pixels from an image to effectively turn an area-scan camera into a linear camera, when a potential application provided us with a new idea.” Use of IR cameras On papermaking machines, excessive moisture often leads to sheet breaks - a major runnability issue On papermaking machines, excessive moisture often leads to sheet breaks - a major runnability issue. IVS was invited to quote for a project in Poland that sought to use IR cameras instead of a traditional sheet break system. “I had no idea why, so I started investigating,” says Mr Frackowiak. “I discovered that while a few competitors had started using IR cameras for displaying video, they were not doing anything with that output. In a papermaking machine, temperature is inversely proportional to moisture, so we set about developing a new system – ThermoVision - which combines the concept of our existing ProcessVision with FLIR thermal cameras.” Multiple patents to thermal vision This idea has led to the award of multiple patents pertaining to thermal vision - in particular, temperature being inversely proportional to moisture in the papermaking process. Frackowiak added: “Of course, anyone can mentally make that conversion, but a system based on that concept is our patent. I was surprised no one else had thought of it. We’ve also patented specific outputs from the technology, such as predicting sheet breaks and runnability issues.” The FLIR solution Depending on the application, IVS uses either FLIR A50/A500 or A70/A700 FLIR IR thermal cameras Depending on the application, IVS uses either FLIR A50/A500 or A70/A700 FLIR IR thermal cameras. “With their higher resolution, we tend use FLIR A70/A700 models for papermaking machinery applications,” reveals Mr. Frackowiak. “However, ThermoVision can also benefit machines that produce corrugated paper for packaging. We use FLIR A50/A500 series cameras for corrugators as these applications do not require the same level of resolution, helping to minimise costs for customers.” IP66-rated FLIR A50/A500 and A70/A700 series cameras Rugged, IP66-rated FLIR A50/A500 and A70/A700 series cameras offer multiple field-of-view options, image streaming, and simple integration with the specific needs of customers. By providing quick access to thermal characteristics, users of these cost-effective cameras can maximise asset uptime and minimise maintenance costs. Frackowiak added: “In my opinion, FLIR IR cameras are competitively priced considering the capabilities they offer. During my initial research, I came across other thermal cameras of similar specification, but they cost more. We’re incredibly happy with FLIR IR cameras and now standardise on these models.” Seeing is believing A QCS scanner moves back and forth across the sheet, a process that takes anything from seconds to minutes There are essentially two ways of adopting ThermoVision on a papermaking machine. First, as an add-on to existing sheet break systems. FLIR IR cameras see ‘invisible’ defects that visual spectrum cameras cannot. The system also detects wet streaks in real-time, helping to prevent costly sheet breaks that can lead to hours of downtime. Second, the system can involve sending the sheet-wide thermal profile to a quality control system (QCS) scanner. A QCS scanner moves back and forth across the sheet, a process that takes anything from seconds to minutes. However, using data captured by FLIR IR cameras, it is possible to feed the QCS in real-time. While the control system will not likely work in real-time, capturing images with FLIR IR cameras at 30 frames per second, for example, means the system can provide an average profile every second, supporting ultra-fast control system decisions. Positioning a FLIR IR camera “A big issue with a QCS scanner is its location at the end of a papermaking machine,” explains Mr Frackowiak. “From placing pulp on the wire, ready for manufacturing into paper, to running through the entire machine and reaching the QCS scanner, no quality measurement checks take place." "However, by positioning a FLIR IR camera at the beginning of the process, perhaps in the press section, we can immediately detect defects like wet streaks or incorrect moisture profiles. This is important because some start-up processes can take hours, with papermaking plants unable to thread the web due to problematic sheet breaks. We now have a way of letting them know why, saving significant time.” Advantages of the technology IVS has two papermaking systems running with ThermoVision in the USA Several papermaking facilities are already taking advantage of the technology. Following the award of its patents, IVS now has two papermaking systems running with ThermoVision in the USA, as well as a corrugator. Multiple quotations have been sent to further potential customers, with some planning to include ThermoVision in their next capital expenditure budget. Capabilities of FLIR IR cameras With the right innovation and technology, even a mature process like papermaking can see step changes in key metrics - such as quality, efficiency, uptime, and control. Thanks to the ingenuity of proprietary IVS systems and the capabilities of FLIR IR thermal vision cameras, papermaking is set to reach a whole new level.

IDS Imaging Development Systems GmbH, market pioneer in industrial machine vision, and Prophesee SA, inventor of the most advanced neuromorphic vision systems, announces that IDS’ new uEye EVS camera line incorporates the high-speed, dynamic range and data efficiency of the Prophesee-Sony IMX636HD event-based vision sensor to offer new capabilities for industrial machine vision applications. High-speed event-based vision The uEye EVS camera redefines high-speed machine vision for unprecedented precision The result of extensive collaboration between the two companies, the solution features Prophesee’s proven neuromorphic approach to capturing fast-moving objects with significantly less data processing, power and blur than traditional frame-based methods. With these capabilities, the uEye EVS camera is the ideal solution for applications that require real-time machine vision processing at very high speed, such as optical monitoring of vibrations or high-speed motion analyses. Conventional image sensors The camera benefits from Prophesee’s event-based vision’s ability to capture only relevant events in a scene. In contrast to conventional image sensors, it does not capture every image completely at regular intervals (frames) but only reacts to changes within a scene. It transmits events depending on when and where the brightness in its field of view changes - for each individual sensor pixel. The temporal resolution, i.e. the minimum measurable time difference between two successive changes in brightness, can be less than 100 microseconds. Metavision SDK integration The sensor is supported by Metavision SDK, a seamlessly integrated suite of software tool The sensor is supported by Metavision SDK, a seamlessly integrated suite of software tools and models, APIs, and other training and development resources from Prophesee for efficient evaluation, visualisation, and customisation. "This partnership combines our mutual areas of expertise to realise the benefits of event-based vision, including remarkable temporal resolution which make the cameras optimised for analysing highly dynamic scenes.” “It enables best conditions for capturing fast object movements without loss of information, comparable to an image-based frame rate of more than 10,000 images per second," explains Patrick Schick, Product Owner 3D & Vision Software. Enhanced efficiency & performance “At the same time, the sensor ignores all motionless areas of its field of view and thus generates 10 to 1000 times less data than image-based variants. This saves memory and computing time. IDS cameras are well known to address the toughest machine vision use cases and with the incorporation of Prophesee event-based vision technologies.” “It strengthens its offering to provide far more performance, power efficiency and accuracy, even in the most challenging conditions,” says Luca Verre, CEO and co-founder of Prophesee. “We are excited to see how the efforts of this tight collaboration have resulted in the new uEye EVS camera which leverages the potential of our sensors and development environment to deliver new value to its customers.”

Uncover the basics of infrared technology, explore different sensor types, and learn about radiometric calibration. Infrared imaging radiometry is the science of using an infrared camera to measure the amount of IR radiation from a target in a scene. Every pixel in the image formed by a radiometrically calibrated camera carries quantitative information. Understanding infrared radiometry Radiometric images are more than just pictures; they are precise grids of infrared rays Radiometric images are more than just pictures; they are also two-dimensional grids of measurements of the infrared radiation imaged onto the sensor from the scene. The camera lens “maps” the IR radiation emitted from objects in the scene to corresponding positions on the sensor. The applications for infrared radiometry are plentiful, and well understood by scientists and engineers that work with this equipment. Matthew Hasty, Global Senior Product Manager, Research and Development and Automation Segments at FLIR will explore the fundamentals of infrared technology, how it works, and the various sensor technologies available. Hasty will also demonstrate how software, particularly FLIR Research Studio, can enhance efficiency and drive scientific discovery for global teams in innovative ways. Enhance scientific discovery Learn how users can drive scientific discovery with imaging radiometry and FLIR technology with industry expert Matt Hasty. Don't miss this opportunity on March 27th, 11AM ET with live Q&A. Join them and walk away with: Fundamental understanding of infrared technology What are the different sensor types Importance of radiometric calibration How to use software to enhance efficiency Don't miss this opportunity to stay ahead of the curve and elevate skills. Register now and continue on the quest for scientific breakthroughs!

At ISC West 2025, on booth #10037, i-PRO Co., Ltd. (formerly Panasonic Security), a pioneer in professional security solutions for security and public safety, will unveil its latest advancements in edge computing cameras, featuring AI-driven analytics, advanced cybersecurity, and mission-critical reliability. With a focus on adaptability, cybersecurity, and made-in-Japan technology, i-PRO will showcase why it stands behind its cameras with a 7-year warranty—a testament to its long-term reliability and superior engineering. High-zoom AI security cameras Enhancing situational awareness with intelligent zoom, and identifying threats in real timeAttendees can explore i-PRO’s newest High-Zoom Bullet Camera lineup, designed for long-range security with powerful infrared (IR) capabilities and edge-processed AI analytics. These cameras feature automatic zoom functionality that enhances situational awareness. For example, the camera can remain in a wide-angle view until it detects a person or vehicle at a gate or entrance, at which point it instantly zooms in to facilitate positive identification and license plate recognition. Aero PTZ withstands extreme conditions Another highlight is the Aero PTZ Camera, built to withstand category five hurricanes and extreme temperatures. Offering the longest nighttime IR illumination among PTZ cameras and supporting up to three simultaneous AI applications. This rugged device is one of the most advanced AI-powered PTZ cameras on the market today. i-PRO also plans to announce a new line of edge-processing cameras at ISC-West. Commitment to security & reliability "Along with our latest innovative cameras, i-PRO remains committed to cybersecurity, data privacy, and unparalleled reliability,” said Gerard Figols, Chief Product Officer at i-PRO. “Our industry-leading 7-year warranty is a testament to our confidence in our products and why integrators trust us to deliver exceptional business value for every installation." Additional featured security products at ISC West: X-Series Cameras with CV52 SoC – The industry’s first AI On-Site Learning Analytics solution, featuring AI Processing Relay for non-AI cameras and NextGen Ambarella Chipset with Docker Container support. Corner Camera – Designed for correctional facilities, this ultra-durable, shock-resistant camera features advanced tamper detection and an industry-first IK11+ rating. Active Guard 2.0 – A data-driven forensic search and alert platform for rapid threat identification. Version 2 includes new enhancements for data search and visualisation. New integrations with third-party developers bring valuable new metadata directly into the VMS UI for the first time. VideoInsight™ VMS and MonitorCast Access Control – A comprehensive security solution that streamlines operations, reduces costs, and enhances situational awareness in educational institutions. A new update to VideoInsight will be unveiled at ISC-West for the first time. BWC4000 body-worn camera – Features seamless integration with in-car video systems and the Video Insight VMS. Includes a 12-hour field-swappable battery for extended use.

Data centre maintenance teams have a big share in safeguarding the critical resource that customers and businesses depend upon. Fortunately, they have one secret weapon that enables them to spot issues in an early stage before they turn into big problems: FLIR thermal imaging. The data centre market has seen a massive growth in recent years. Spurred by a growing adoption of cloud technologies, AI, IoT, 5G and big data, new data centres are being built across all continents at fast pace. Whether they are in-house data centres for some of the largest and most influential companies, or built by specialised vendors offering infrastructure services, data centres fulfill a critical role in maintaining the continuity of a business. Downtime of a data centre Guaranteeing uptime has become increasingly complex for data centres Downtime of a data centre can have an enormous economic impact and needs to be avoided at all costs. In addition to financial loss, reputational damage can be equally impactful, especially when the data centre is supporting customer-facing services. Guaranteeing uptime has become increasingly complex for data centres. With so much mechanical, electrical and electronic infrastructure under one roof, overheating is a major concern, not only because the infrastructure is not using the energy efficiently, but also because overheating can cause a complete shutdown of servers, impacting users around the world, or even data or equipment loss. One of the most reported incidents is the 2013 overheating of a Microsoft data centre operating some of its cloud services, including Outlook, which led to services being lost for 16 hours. Maintenance inspections with thermal imaging cameras The maintenance of a data centre today involves much more than IT operations. Power distribution systems and cooling infrastructure are also essential for keeping the data centre up and running, and for preventing mechanical or electrical failures and resulting outages. Many systems that are critical for the data centre’s operation heat up before they fail. Temperature is an important indicator of energy consumption and equipment operation, which is why infrared thermography (thermal imaging) is an ideal tool to inspect power consumption, electrical installations, cooling equipment and computing hardware. Periodic inspections with thermal imaging camera Thermal cameras help maintenance staff to detect problems in electrical switchgear, motors Periodic inspections with a thermal imaging camera have become indispensable in predictive and preventive maintenance programs. Thermal cameras help maintenance staff to detect problems in electrical switchgear, motors, HVAC infrastructure, uninterruptible power supplies (UPS), power distribution units (PDU), batteries and generator equipment and all electrical devices that feed the server systems, before these problems turn into serious failures or downtime. Rise of cloud computing With cloud computing becoming the new normal, and as data centres are growing to great scales, the need for higher computing density and power efficiency is growing as well. Data centre owners are seeking ways to increase their capacity, but they also want to reduce costs and energy. Thermal imaging can give them important information on how to optimise energy and space requirements, without causing overheating. In short, regular inspections with thermal imaging cameras can help maintenance staff to: Find and fix hidden problems before they turn into unplanned downtime. Reduce the chance of component degradation going unnoticed due to overloaded circuits or loose connections. Prevent equipment breakdowns. Optimise energy management and space allocation. What is Thermal Imaging? A thermal camera is a non-contact device that detects infrared energy (heat) A thermal camera is a non-contact device that detects infrared energy (heat) and converts it into a visual image. Infrared radiation lies between the visible and microwave portions of the electromagnetic spectrum. Any object that has a temperature above absolute zero (-273.15 degrees Celsius or 0 Kelvin) emits radiation in the infrared region. Even objects that are very cold, such as ice cubes, emit infrared radiation. Thermal cameras turn this invisible energy into something that can be seen on a screen and measured. The Benefit of Thermal Imaging Why to choose a FLIR thermal imaging camera? Sure, there are other technologies available to help measure temperatures – infrared thermometers or thermocouples to name only two. But no other tool is as powerful and efficient as a FLIR thermal imaging camera. See the whole picture Unlike IR thermometers or thermocouples, thermal imaging cameras enable to scan large areas for hot spots or temperature differences. Without a thermal camera, it’s easy to miss critical parts like air leakages, areas with insufficient insulation or water intrusion. A thermal imaging camera can scan entire electrical installations, buildings A thermal imaging camera can scan entire electrical installations, buildings, heating or HVAC installations. It never misses a potential problem area no matter how small this might be. They also allow to compare temperatures of components in the same environment more easily. Save time and costs Maintenance of data centre installations can be labour-intensive. Because they can easily see larger surfaces, thermal imaging cameras can be the solution to reduce maintenance time speed up inspection rounds, and still see all impending failures, before they turn into costly defects. Inspect without shutting down Thermal imaging is a non-contact technology. This is a safe method, because maintenance personnel can keep a distance without having to touch hot items. But it also means that inspections can easily be carried out while the equipment is still running or under load. There’s no need to foresee costly downtime. Some inspections, for example rotary UPS systems, can only be done during operation, which makes the thermal imaging camera an ideal tool for online inspections. Report Like a Pro Users can compare current inspections with historical data and discover trends Thermal imaging cameras allow users to make professional, more insightful reports of their inspections that also look great for management and customers. Users can compare current inspections with historical data and discover trends. Features like templates, batch processing, image editing and route planning further enhance the use-friendliness of today’s reporting solutions. Thermal imaging applications Thermal imaging is the perfect technology to tackle the wide range of maintenance and inspection jobs for data centres. Electrical and Mechanical Systems Thermal imaging cameras can be used to inspect a variety of electrical or power generation-related systems. Heat is an important indicator for defects in electrical installations. When current passes through a resistive element, it generates heat. Over time, the resistance of electrical connections can increase, due to loosening and corrosion for instance. The corresponding rise in temperature can cause components to fail, resulting in unplanned outages. Electrical systems can also suffer from load imbalances and increases in impedance to current. Thermal inspections can quickly locate hot spots, determine the severity of the problem, and help establish the time frame in which the equipment should be repaired. Thermal imaging cameras will help you to spot issues with: Overheated connections Overloaded or imbalanced circuits Damaged switches Faulty fuses Power supplies Battery systems Generator systems Uninterruptible Power Supplies (UPS) Transformers Electrical panels Resistive load banks HVAC and Cooling Systems To run smoothly and efficiently, data centres need perfectly air-cooled conditions To run smoothly and efficiently, data centres need perfectly air-cooled conditions. Data centres are typically making use of a hot aisle/cold aisle layout principle. Server racks are lined up in aisles with the front sides facing each other. The cold aisles get cold air directly from the Computer Room Air-Conditioning (CRAC) unit from the bottom of the raised floor. The cool air cools down the servers on the racks. Meanwhile, the backs of the servers vent out hot air in the hot aisle, which then returns to the CRAC unit. Thermal imaging has become increasingly important to verify the proper hot aisle/cold aisle operation, especially because data centres today are condensing more servers into their racks. Thermal cameras will enable users to see problems such as misaligned ductwork and electrical faults, and then make decisions about corrective actions. HVAC inspection with a thermal imaging camera can help to: Monitor server rack temperature distribution patterns Locate misrouted and leaking ducts See electrical or mechanical CRAC unit defects Confirm the source of energy losses Find missing insulation Discover AC condensate leaks Find internal server fans which are inoperable or damaged Renewable Energy Data centre operators are increasingly improving their use of renewable energy sources Data centre operators are increasingly improving their use of renewable energy sources, including solar and wind power. These renewable power sources enable data centres to reduce their environmental impact, while meeting long-term sustainability goals. Solar Power The solar panel, the most important part of a solar system, must be reliable and capable of producing electricity for years on end. Unfortunately, solar panels are susceptible to wear. Maintenance professionals therefore use thermal imagers to inspect solar panels installed on rooftops or in solar parks to quickly pinpoint solar panel problems down to cell level. Anomalies can clearly be seen on a crisp thermal image and - unlike most other methods - thermal imaging cameras can be used to scan installed solar panels during normal operation. Thermal imaging cameras also allow users to scan large areas within a short time frame. Wind Power Wind turbine components are susceptible to wear and can break down. That’s why preventive maintenance and periodic inspections are so important. Thermal imaging is the only technology that allows users to inspect all electrical and mechanical components of the wind turbine and the surrounding electrical system, so they can detect a problem before a breakdown occurs. Fire Protection Although data centre fires are relatively rare, they can have a devastating impact Although data centre fires are relatively rare, they can have a devastating impact. Data centres may be equipped with fire alarms and firefighting systems, but once a fire starts, asset damage is almost certain. Fixed thermal imaging cameras can identify hot spots before they ignite and provide an early warning response to avoid a full-on destructive fire before assets are harmed or safety is compromised. Physical Security Thermal cameras not only detect hot spots or temperature differences. They also help protect a physical perimeter against unwanted intruders or trespassers. As data centres operate 24/7, they need effective solutions to help them monitor the premises and detect threats around the clock. Thermal security cameras that offer high contrast, high resolution and long detection ranges are ideal for data centre deployments. 4/5 Unlike standard video cameras, thermal cameras can see in most adverse weather conditions– such as light rain, fog, smoke, or total darkness. When integrated with video analytics, thermal cameras can distinguish between a human or vehicle. When paired with radar, customers gain redundancy and reduce the likelihood of a false positive. By combining thermal cameras with HD visible cameras, remote operators can review thermal and visible video streams of the scene for improved alarm verification and intruder identification. Thermal Imaging Solutions from Teledyne FLIR Handheld thermography cameras FLIR thermography cameras always offer the highest accuracy and user-friendliness Armed with a FLIR thermal imaging camera, maintenance crews can easily diagnose a wide range of problems across their data centre facility. Available in a wide variety of sizes and image resolutions, FLIR thermography cameras always offer the highest accuracy and user-friendliness to meet the needs of maintenance professionals. Thermal Studio Software with Route Creator FLIR Thermal Studio Suite is state-of-the-art analysis and reporting software designed to help data centre maintenance teams manage thousands of thermal images and videos. Whether using handheld thermal cameras or unmanned aircraft systems (UAS), the FLIR Thermal Studio suite of software provides the automation and processing capabilities needed to streamline workflow and increase productivity. The optional Route Creator plugin allows users to plan inspection routes in advance, complete inspections more efficiently and reduce reporting time by 50%. FLIR CARE’s traceable calibration services Keep the thermal camera in optimal performance condition and avoid unforeseen downtime with a FLIR CARE service package. Whether looking for a performance verification service or a traceable calibration adjustment service, FLIR CARE’s traceable calibration services have covered everything. FLIR PROTECT Service Packages FLIR PROTECT Extended Warranty and Service Packages give the peace of mind that the camera is protected from material defects and issues for three years after the factory warranty expires. Choose FLIR Protect+, FLIR Protect Pro, or FLIR Total Protect to bundle a discounted FLIR CARE Service with the FLIR PROTECT extended warranty.

Brady Corporation offers a new, more cost-efficient solution to quickly detect unstable Li-ion batteries in storage. Able to automatically measure 0,5°C temperature differences per second, the solution provides the accuracy and speed needed to isolate unstable batteries before they become a safety risk. Brady’s new battery temperature monitoring solution involves three components: self-adhesive battery-free UHF RFID labels with embedded temperature sensors, RFID readers with up to 16 antennas, and a customisable RFID software platform. RFID software platform RFID antennas and readers automatically power all labels and sensors in range to pile temperature readings The self-adhesive UHF RFID-embedded labels can be applied inside battery cell boxes for fast temperature change detection. Alternatively, every battery cell can be labelled with Brady’s on-metal, printable UHF RFID labels to enable more elaborate advantages in Li-ion battery supply chains. Every second, the RFID antennas and readers automatically power all labels and sensors in range to collect temperature readings with 0.5°C accuracy. Every temperature reading, and matching battery storage location, is collected by the RFID software platform. When customisable temperature thresholds are reached, the software platform triggers third-party devices via standard API. Brady’s software platform API With almost continuous, automated and accurate temperature monitoring, warehouse stakeholders can receive early warnings via sms, email or even racking warning lights. They can be guided in time to specific warehouse locations for unstable Li-ion battery isolation. Alternatively, Brady’s software platform API can also trigger an autonomous vehicle to automatically remove an unstable battery. RFID tags or IR cameras Battery-free UHF RFID labels with embedded sensors are a more cost-effective battery temperature monitoring solution than powered RFID tags or IR cameras. UHF RFID labels and their temperature sensors receive power wirelessly from RFID antennas and readers in range. They are available at significantly lower costs - up to five times less than battery-powered RFID tags-and do not require maintenance. Temperature monitoring solution Brady connects up to 16 antennas to a single RFID reader that provides high accuracy and high-speed The number of RFID readers needed to completely cover storage locations in a warehouse heavily depends on warehouse setup, racking height and storage volume per racking compartment. Brady can connect up to 16 antennas to a single RFID reader that provides high accuracy, high-speed temperature monitoring for all storage locations in 12-metre-wide and 4-metre high racking. The automated, and almost continuous, nature of the temperature monitoring solution enables Li-ion battery manufacturers and logistics companies to significantly increase safety and reduce risk at advantageous costs. Brady’s RFID readers By adding an RFID reader gate at designated warehouse exits, Brady’s solution can also enable automated, real-time warehouse inventories. RFID labelled items are read by Brady’s RFID readers the moment their label enters reader range. When they pass through a designated RFID reader gate, these items can easily be subtracted from the inventory by the RFID software platform. When used in this way, the solution can provide cost-effective battery track & trace inside the warehouse from entry to exit, complete with battery cell box or battery cell temperature fluctuation in between.

Industrial Video Solutions Inc (IVS), a US-based specialist in automation for the papermaking industry, is leveraging FLIR infrared (IR) thermal cameras to obtain valuable data from paper machines as part of a patented system that boosts machine control and efficiency. Moisture and temperature directly affect both paper properties and machine runnability making the measurement of these parameters essential to the papermaking process. However, despite the presence of visual spectrum cameras in several machine locations, some aspects of the papermaking process remain invisible to operators. This problem is attributable to factors such as steamy operating environments, visual camera limitations, and a lack of tools that convert camera images into actionable data. IVS-patented system With its FLIR cameras, ThermoVision sees real-time moisture profiles in any paper machine location The solution arrives in the shape of ThermoVision, an IVS-patented system featuring FLIR IR cameras at its core. With its FLIR cameras, ThermoVision sees real-time moisture profiles in any paper machine location, mapping them to a multi-functional thermal profiler. The system can provide real-time, full-width, cross-direction (CD) moisture and temperature profiles, as well as real-time machine direction (MD) profile variations. Moreover, profile analytics provide insights into dewatering and drying efficiency - critical for energy benchmarking. Real-time detection ThermoVision facilitates the real-time detection and classification of wet streaks and spots, as well as the real-time detection of embedded foreign materials, such as metals in fluff pulp. A key capability of the system is its ability to provide visibility in steamy machine locations. Using a FLIR IR camera to capture an image of a pulper vortex, for example, allows users to see through the steam and visualise the vortex in full detail, including the position of the chain and vortex edges. This ability is indispensable for monitoring locations within the machine like trim squirts and dryers. IR and visual spectrum cameras It is even possible to feed data from a combination of IR and visual spectrum cameras to an AI module While it only requires a single FLIR IR camera to execute all ThermoVision analyses, multi-camera systems are more effective for complete process troubleshooting, optimisation, and improvement. It is even possible to feed data from a combination of IR and visual spectrum cameras to an artificial intelligence (AI) module. This neural network learns the relationship between the forces exerted on the paper, paper vulnerabilities, and process upsets - such as sheet breaks - with the goal of predicting runnability issues. Seven-figure savings “Armed with new data for maximising paper machine performance, we estimate substantial savings for ThermoVision users,” says Slawek Frackowiak, President and CEO of IVS. “For example, reductions in energy consumption and paper breaks, alongside increases in productivity, can lead to annual savings in the region of $1.3 million on a 300,000-ton liner-board machine.” He continues: “We came across the potential for this technology by chance. We had already patented our ProcessVision technology, which extracts pixels from an image to effectively turn an area-scan camera into a linear camera, when a potential application provided us with a new idea.” Use of IR cameras On papermaking machines, excessive moisture often leads to sheet breaks - a major runnability issue On papermaking machines, excessive moisture often leads to sheet breaks - a major runnability issue. IVS was invited to quote for a project in Poland that sought to use IR cameras instead of a traditional sheet break system. “I had no idea why, so I started investigating,” says Mr Frackowiak. “I discovered that while a few competitors had started using IR cameras for displaying video, they were not doing anything with that output. In a papermaking machine, temperature is inversely proportional to moisture, so we set about developing a new system – ThermoVision - which combines the concept of our existing ProcessVision with FLIR thermal cameras.” Multiple patents to thermal vision This idea has led to the award of multiple patents pertaining to thermal vision - in particular, temperature being inversely proportional to moisture in the papermaking process. Frackowiak added: “Of course, anyone can mentally make that conversion, but a system based on that concept is our patent. I was surprised no one else had thought of it. We’ve also patented specific outputs from the technology, such as predicting sheet breaks and runnability issues.” The FLIR solution Depending on the application, IVS uses either FLIR A50/A500 or A70/A700 FLIR IR thermal cameras Depending on the application, IVS uses either FLIR A50/A500 or A70/A700 FLIR IR thermal cameras. “With their higher resolution, we tend use FLIR A70/A700 models for papermaking machinery applications,” reveals Mr. Frackowiak. “However, ThermoVision can also benefit machines that produce corrugated paper for packaging. We use FLIR A50/A500 series cameras for corrugators as these applications do not require the same level of resolution, helping to minimise costs for customers.” IP66-rated FLIR A50/A500 and A70/A700 series cameras Rugged, IP66-rated FLIR A50/A500 and A70/A700 series cameras offer multiple field-of-view options, image streaming, and simple integration with the specific needs of customers. By providing quick access to thermal characteristics, users of these cost-effective cameras can maximise asset uptime and minimise maintenance costs. Frackowiak added: “In my opinion, FLIR IR cameras are competitively priced considering the capabilities they offer. During my initial research, I came across other thermal cameras of similar specification, but they cost more. We’re incredibly happy with FLIR IR cameras and now standardise on these models.” Seeing is believing A QCS scanner moves back and forth across the sheet, a process that takes anything from seconds to minutes There are essentially two ways of adopting ThermoVision on a papermaking machine. First, as an add-on to existing sheet break systems. FLIR IR cameras see ‘invisible’ defects that visual spectrum cameras cannot. The system also detects wet streaks in real-time, helping to prevent costly sheet breaks that can lead to hours of downtime. Second, the system can involve sending the sheet-wide thermal profile to a quality control system (QCS) scanner. A QCS scanner moves back and forth across the sheet, a process that takes anything from seconds to minutes. However, using data captured by FLIR IR cameras, it is possible to feed the QCS in real-time. While the control system will not likely work in real-time, capturing images with FLIR IR cameras at 30 frames per second, for example, means the system can provide an average profile every second, supporting ultra-fast control system decisions. Positioning a FLIR IR camera “A big issue with a QCS scanner is its location at the end of a papermaking machine,” explains Mr Frackowiak. “From placing pulp on the wire, ready for manufacturing into paper, to running through the entire machine and reaching the QCS scanner, no quality measurement checks take place." "However, by positioning a FLIR IR camera at the beginning of the process, perhaps in the press section, we can immediately detect defects like wet streaks or incorrect moisture profiles. This is important because some start-up processes can take hours, with papermaking plants unable to thread the web due to problematic sheet breaks. We now have a way of letting them know why, saving significant time.” Advantages of the technology IVS has two papermaking systems running with ThermoVision in the USA Several papermaking facilities are already taking advantage of the technology. Following the award of its patents, IVS now has two papermaking systems running with ThermoVision in the USA, as well as a corrugator. Multiple quotations have been sent to further potential customers, with some planning to include ThermoVision in their next capital expenditure budget. Capabilities of FLIR IR cameras With the right innovation and technology, even a mature process like papermaking can see step changes in key metrics - such as quality, efficiency, uptime, and control. Thanks to the ingenuity of proprietary IVS systems and the capabilities of FLIR IR thermal vision cameras, papermaking is set to reach a whole new level.

IDS Imaging Development Systems GmbH, market pioneer in industrial machine vision, and Prophesee SA, inventor of the most advanced neuromorphic vision systems, announces that IDS’ new uEye EVS camera line incorporates the high-speed, dynamic range and data efficiency of the Prophesee-Sony IMX636HD event-based vision sensor to offer new capabilities for industrial machine vision applications. High-speed event-based vision The uEye EVS camera redefines high-speed machine vision for unprecedented precision The result of extensive collaboration between the two companies, the solution features Prophesee’s proven neuromorphic approach to capturing fast-moving objects with significantly less data processing, power and blur than traditional frame-based methods. With these capabilities, the uEye EVS camera is the ideal solution for applications that require real-time machine vision processing at very high speed, such as optical monitoring of vibrations or high-speed motion analyses. Conventional image sensors The camera benefits from Prophesee’s event-based vision’s ability to capture only relevant events in a scene. In contrast to conventional image sensors, it does not capture every image completely at regular intervals (frames) but only reacts to changes within a scene. It transmits events depending on when and where the brightness in its field of view changes - for each individual sensor pixel. The temporal resolution, i.e. the minimum measurable time difference between two successive changes in brightness, can be less than 100 microseconds. Metavision SDK integration The sensor is supported by Metavision SDK, a seamlessly integrated suite of software tool The sensor is supported by Metavision SDK, a seamlessly integrated suite of software tools and models, APIs, and other training and development resources from Prophesee for efficient evaluation, visualisation, and customisation. "This partnership combines our mutual areas of expertise to realise the benefits of event-based vision, including remarkable temporal resolution which make the cameras optimised for analysing highly dynamic scenes.” “It enables best conditions for capturing fast object movements without loss of information, comparable to an image-based frame rate of more than 10,000 images per second," explains Patrick Schick, Product Owner 3D & Vision Software. Enhanced efficiency & performance “At the same time, the sensor ignores all motionless areas of its field of view and thus generates 10 to 1000 times less data than image-based variants. This saves memory and computing time. IDS cameras are well known to address the toughest machine vision use cases and with the incorporation of Prophesee event-based vision technologies.” “It strengthens its offering to provide far more performance, power efficiency and accuracy, even in the most challenging conditions,” says Luca Verre, CEO and co-founder of Prophesee. “We are excited to see how the efforts of this tight collaboration have resulted in the new uEye EVS camera which leverages the potential of our sensors and development environment to deliver new value to its customers.”

Uncover the basics of infrared technology, explore different sensor types, and learn about radiometric calibration. Infrared imaging radiometry is the science of using an infrared camera to measure the amount of IR radiation from a target in a scene. Every pixel in the image formed by a radiometrically calibrated camera carries quantitative information. Understanding infrared radiometry Radiometric images are more than just pictures; they are precise grids of infrared rays Radiometric images are more than just pictures; they are also two-dimensional grids of measurements of the infrared radiation imaged onto the sensor from the scene. The camera lens “maps” the IR radiation emitted from objects in the scene to corresponding positions on the sensor. The applications for infrared radiometry are plentiful, and well understood by scientists and engineers that work with this equipment. Matthew Hasty, Global Senior Product Manager, Research and Development and Automation Segments at FLIR will explore the fundamentals of infrared technology, how it works, and the various sensor technologies available. Hasty will also demonstrate how software, particularly FLIR Research Studio, can enhance efficiency and drive scientific discovery for global teams in innovative ways. Enhance scientific discovery Learn how users can drive scientific discovery with imaging radiometry and FLIR technology with industry expert Matt Hasty. Don't miss this opportunity on March 27th, 11AM ET with live Q&A. Join them and walk away with: Fundamental understanding of infrared technology What are the different sensor types Importance of radiometric calibration How to use software to enhance efficiency Don't miss this opportunity to stay ahead of the curve and elevate skills. Register now and continue on the quest for scientific breakthroughs!

At ISC West 2025, on booth #10037, i-PRO Co., Ltd. (formerly Panasonic Security), a pioneer in professional security solutions for security and public safety, will unveil its latest advancements in edge computing cameras, featuring AI-driven analytics, advanced cybersecurity, and mission-critical reliability. With a focus on adaptability, cybersecurity, and made-in-Japan technology, i-PRO will showcase why it stands behind its cameras with a 7-year warranty—a testament to its long-term reliability and superior engineering. High-zoom AI security cameras Enhancing situational awareness with intelligent zoom, and identifying threats in real timeAttendees can explore i-PRO’s newest High-Zoom Bullet Camera lineup, designed for long-range security with powerful infrared (IR) capabilities and edge-processed AI analytics. These cameras feature automatic zoom functionality that enhances situational awareness. For example, the camera can remain in a wide-angle view until it detects a person or vehicle at a gate or entrance, at which point it instantly zooms in to facilitate positive identification and license plate recognition. Aero PTZ withstands extreme conditions Another highlight is the Aero PTZ Camera, built to withstand category five hurricanes and extreme temperatures. Offering the longest nighttime IR illumination among PTZ cameras and supporting up to three simultaneous AI applications. This rugged device is one of the most advanced AI-powered PTZ cameras on the market today. i-PRO also plans to announce a new line of edge-processing cameras at ISC-West. Commitment to security & reliability "Along with our latest innovative cameras, i-PRO remains committed to cybersecurity, data privacy, and unparalleled reliability,” said Gerard Figols, Chief Product Officer at i-PRO. “Our industry-leading 7-year warranty is a testament to our confidence in our products and why integrators trust us to deliver exceptional business value for every installation." Additional featured security products at ISC West: X-Series Cameras with CV52 SoC – The industry’s first AI On-Site Learning Analytics solution, featuring AI Processing Relay for non-AI cameras and NextGen Ambarella Chipset with Docker Container support. Corner Camera – Designed for correctional facilities, this ultra-durable, shock-resistant camera features advanced tamper detection and an industry-first IK11+ rating. Active Guard 2.0 – A data-driven forensic search and alert platform for rapid threat identification. Version 2 includes new enhancements for data search and visualisation. New integrations with third-party developers bring valuable new metadata directly into the VMS UI for the first time. VideoInsight™ VMS and MonitorCast Access Control – A comprehensive security solution that streamlines operations, reduces costs, and enhances situational awareness in educational institutions. A new update to VideoInsight will be unveiled at ISC-West for the first time. BWC4000 body-worn camera – Features seamless integration with in-car video systems and the Video Insight VMS. Includes a 12-hour field-swappable battery for extended use.

Expert commentary

The autumn equinox, which marks the start of autumn, occurs this weekend on Saturday, September 23. With darker evenings ahead, the experts at ADT have shared five ways to maximise your home's security. Author's quote Michele Bennett, General Manager at ADT UK&I comments: “Opportunistic thieves use darkness to their advantage, so it’s no surprise that the number of burglaries committed increases when the darker nights draw in." He adds, "Our 2022 burglary report found that burglaries are most common at night, with 58% of burglaries occurring between 6 p.m. and 6 a.m. Taking steps to optimise your home’s security before the clocks go back this year will provide reassurance that your property is as secure as possible.” Five ways to secure your property: Get a monitored alarm installed: A visible alarm system is a strong deterrent to potential burglars, as criminals are less likely to target a home that is protected. In the event of a break-in, a monitored alarm will alert you, your keyholders and depending on the package you take out, the police, ensuring a swift response to an alarm activation. Light up the dark: Well-lit exteriors make your home less appealing to potential intruders. Install motion-activated lights around any entry points, particularly porches and gardens, which alert you to movement on your property. This will also prevent burglars from operating under the cloak of darkness and increase the chance of a passerby spotting suspicious activity. Trim your garden landscape: Thieves look for escape routes and hiding spots when deciding which homes to break into, making gardens with high, overgrown hedges more likely to be targeted. This is especially true in the darker evenings, so be sure to give your garden a thorough tidy-up to make your property less likely to be targeted. It’s also advisable to ensure any tools are locked away in sheds and garages that could assist a burglar such as ladders, or a garden spade to force entry. Be smart with your lights: Using smart plugs allows you to turn on a few well-appointed lights and radios or televisions from any location from your phone. Used in conjunction with an outdoor camera or video doorbell, you can have lamps plugged into smart plugs come on when motion is detected. Programming lights to come on at different times throughout the night will help to deter burglars by making your property look occupied. Purchase a smart doorbell or outdoor camera: Smart doorbells are an effective way to deter burglars as they provide evidence in the event of a break-in, package theft, or other suspicious activity around your home. They also notify you when someone is at your door reducing the chance of you being caught out by a late evening or early morning robbery. Further encroachment Smart doorbells also act as a deterrent to unscrupulous door-to-door sellers and con artists, as video footage is recorded. In the event of a late-night door knock, you can see and speak to whoever is at your front door, without having to open the door. ADT’s new outdoor camera also has two-way audio and a high-pitch deterrent siren so you can warn off anyone from your property to deter any further encroachment.

Nowadays to save costs by making full use of old devices while upgrading the old security projects, many integrators or installers prefer to use video management software to manage multiple brands of video devices (such as IP cameras, and NVR), instead of only one single brand. So that they could have more flexible choices to earn profits while saving costs. Multi-brands video device management On other hand, with market segmentation and specialisation, instead of managing the video by themselves, application service providers of different industries prefer video surveillance companies could help them to collect the video from various brands of front-end video devices. Thus they could focus more on application development according to the characteristic of different industries. Therefore to meet the requirements of the surveillance market, how to manage multi-brand video devices has become very important, especially for third-party video management software companies. Then how to manage multi-brands multi-brands video devices (such as IP cameras, and NVR) with your VMS system? The first step is: integration Preparing your system for video devices integration Selecting an open architecture VMS system allows for a deeper, seamless level of integration There’s more to integration than just the ability to plug in a video device. Does your VMS allow you to take advantage of the latest IP camera and other video device technologies? Does it support open architecture? Closed architecture systems offer limited integration. Selecting an open architecture VMS system allows for a deeper, seamless level of integration, and allows you to upgrade hardware at your own pace. It also allows you to expand your suite of security solutions in the future, as your needs change. Choosing a VMS system And these questions also need to be considered when choosing a suitable VMS system: Does your system support multiple protocols to communicate with video devices? Can your system easily integrate the private SDK provided by the IP camera manufacturer? Make sure the communication between multi-brand video devices (such as IP cameras, NVR) and your video surveillance VMS system can be put through. ONVIF Nowadays most famous overseas video surveillance manufacturers all support the standard protocol ONVIF, which enable VMS system easily to access their video devices (such as IP cameras, and NVR). Some will provide protocols like RTSP, HLS, HTTP-FLV, and Websocket. Some will provide their private protocols like EHOME/ISUP protocol and DHOME. And also GB/T28181, and GA/T1400 protocols are very popular in China. Simple and easy integration As for the VMS system, the more protocols it supports, the easier it can put through communication As for the VMS system, the more protocols it supports, the easier it can put through communication with the front-end video devices. Thus it will make the whole process of integration simple and easy. And about video surveillance manufacturers who only can provide SDK, in this way open architecture of VMS system is needed because it can help to put through the communication smoothly. The second step is management Since communication between front-end video devices and the VMS system is put through. VMS system can access, capture, and collect the video from the network video devices (both live and recorded). It then stores that video to dedicated data storage media (on-premises, external locations, or in the cloud), based on automated policies, pre-determined by the organisation. That is how a VMS system work. But if the front-end devices are different, they are using a different format, bitrate, and resolution. For example, one brand of IP camera uses H.265, 4K resolution, and the other brand of IP camera use H.264, 1080P. How can a VMS system manage them together? Video transcoding technology That requires the VMS system should have efficient video transcoding technology to convert different video formats and resolutions into unified video formats and resolutions, and strong video transmission technology to meet low bandwidth network adaptability. Smooth streaming automatically adjusts bit-rate and resolution between the VMS system and front-end devices according to real-time network conditions. For example: The video with a high bitstream can be converted to a low bitstream. 8K,4K,3M, 10 80P. .. → D1,CIF,VGA... Transcode video in different encoding formats to the unified encoding formats. H.265, MPEG4 → H.264 The third step: output standard video data for the third-party integration A good VMS system should provide convenient ways for several video processing applications. In interactions applications, particularly in media interchange, a good system should output standardised protocols and stream formats (such as HLS, RTSP, WebSocket, etc) according to the needs of the third party, so that the third party can easily acquire and use video from VMS system for the further application or development.