Medical device manufacturers are pioneers in medical device tracking, digitising loaner management to automate their consignment programmes and support SPD traceability.

Consigned surgical instrumentation and devices, such as ortho, implants, scopes, and laparoscopy, have become essential to healthcare facilities. Metal and plastic trays designed to handle and protect them during sterilisation are now available with electronic tags that allow full tracking and digitalisation of consignment programmes.

Medical device tracking software

By incorporating medical device tracking software into their loaners’ workflow, medical vendors benefit directly from streamlining their consigned inventory in the field, as well as its location and identification.

Digitising loaner and consignment management improves patient outcomes

Finally, digitising loaner and consignment management improves patient outcomes, by improving surgical case coordination, scheduling between institutions and vendors, reducing pre-op notification lead time and increasing overall accountability.

Supporting SPD traceability

SPD departments are still learning to deal with the added complexity stemming from loaner instrumentation management and medical device tracking software can help.

The increased number of loaner trays, containers and cassettes pose a logistical challenge, which is exacerbated by the impact on patient safety and service quality: How to decontaminate, process, and handle instruments that are uncommon, rare, or complex? How to get access to their count sheets and usage instructions? How to learn about a loaner set’s history records and document its reprocessing information at the facility?

While the use of loaner instrumentation may be temporary, the SPD is responsible for cleaning, sterilisation, maintenance and inventory integrity, while in the custody of the healthcare institution. As a result, any tracking technology considered must be safe for all standard processing methods, particularly sterilisation: ETO, cold solutions, autoclave/dry heat.

Loaner Instrument Management for the OR

The OR will focus on getting the right instrumentation sets, on time and in the right room, as with all required instrumentation. In addition to reducing inventory-related OR delays, instrumentation sets will be built based on physician preferences. Each instrumentation set prepared for a specific case is labelled to assist perioperative nurses in proactive patient safety.

Eventually, surgical loaner tracking should enable full traceability, with each set associated with a doctor, an operating room, and a procedure, in accordance with UDI requirements.

Upgrading loaner tracking solutions to RFID

Medical device manufacturers are upgrading their loaner tracking solutions to RFID

Medical device manufacturers are upgrading their loaner tracking solutions to RFID. The technology is taking over from the first-generation loaner and consignment programme tracking solutions that used barcodes, QR codes, and other camera/computer vision technologies.

The rationale for the technology upgrade is found in several operational advantages over older tracking solutions. Used with the right medical device tracking software, RFID enables real-time inventory tracking. It allows for inventory automation and is fully operational in the OR, SPD, and in the field, providing full data accuracy.

Moreover, the unique identifiers provided by RFID tags are UDI-compliant for full traceability from manufacturer to patient. RFID has a long history of usage in the medical field and is fully interoperable with existing systems, facilitating the upgrade and its deployment at the facility.

RFID tracking devices

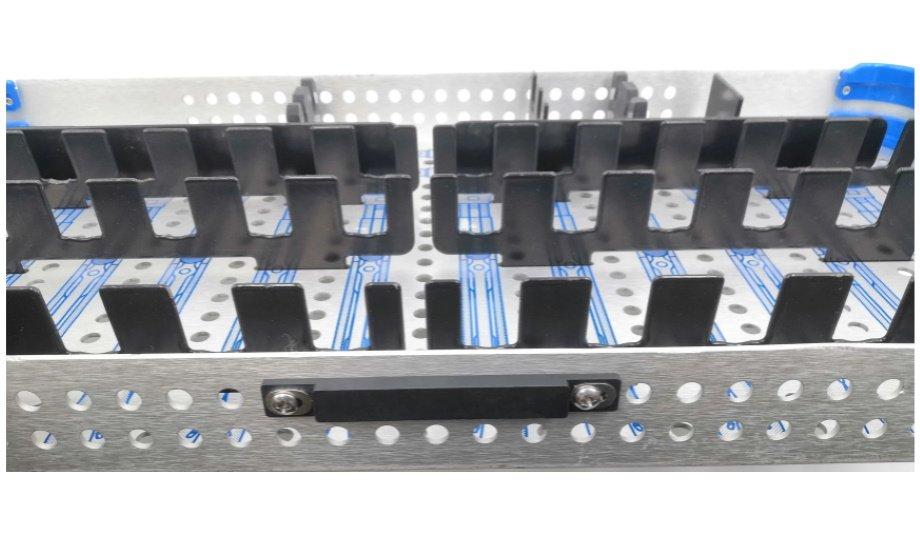

The RFID tracking devices come in the form of Passive UHF RFID tags, designed to be attached to the surgical loaner trays, containers, and cassettes. The RFID tags are made of medical-grade materials, such as 316L stainless steel and engineered plastics. They are shock resistant and processing-safe, being designed to withstand standard processing and sterilisation methods.

The RFID tags fit both metal and plastic trays, and take advantage of existing holes on surgical trays, in order to provide a perfect fit using rivets or screws. The addition of metal inserts ensures a solid bond with the trays throughout the rigors of processing, while the option to use screws allows for easy removal or replacement, if required.

Custom RFID tags services

Xerafy is a pioneer in RFID technology for healthcare and medical applications, bringing to market critical technological innovations that enable advanced identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers custom RFID tags services, covering everything from a personalisation service bureau to custom design engineering capabilities.