|

| The company opted for the weatherproof Q24 camera with 360-degree panorama view for the cooking area |

Java is a popular tourist destination. Some of the main attractions on Indonesia’s most populous island include the capital city Jakarta, Borobudur and Prambanan (UNESCO World Heritage Sites) and the Mount Bromo volcano. Vacationers visiting the supermarket to stock up on drinks on the way to these hotspots will find the shelves lined with Ultra Milk or ready-to-drink teas called Teh Kotak. These brands are widely available in Indonesia and belong to Ultrajaya, the country’s leading producer of milk products, ready-to-drink teas and fruit juices.

The company was founded in the city of Bandung, West Java, in 1958. Today, the production facility is situated in the middle of the fertile agricultural land near the city. This is where the high-quality ingredients used in production are sourced, including milk, tea and tropical fruits. 90 percent of the group’s production volume is sold in Indonesia, with the rest being exported.

Up until 2007, the production processes and outdoor areas of Ultrajaya’s production facility were predominantly monitored using analogue camera systems. "However, these cameras were no longer reliable and were delivering poor quality images," recalls Marvin Bayoumi, Quality Control Manager at Ultrajaya. "What’s more, after a while they fell victim to the high temperatures and humidity that are by-products of the ultra-heat treatment and liquid mixing processes." Over the years, Ultrajaya had also installed IP cameras, which use Internet protocols (IP) to transfer image data and control signals to a video server via an Ethernet or wireless network. However, these also left a lot to be desired in terms of reliability, and the resolution was not really up to the task.

Decentralised system with ’Intelligent’ cameras

That is why Ultrajaya decided to install a completely new camera system to secure their indoor and outdoor areas, as well as the construction site of the new production facility in October 2007. The final decision fell to solutions provided by the renowned German IP video and complete system manufacturer MOBOTIX. Ultrajaya decided to install the MOBOTIX system and PT. Sirca Global Niaga, its Indonesian partner, assisted in the transition process. "We were really impressed by the reliability of the system, the high resolution of the cameras, and above all, the decentralized MOBOTIX system that enables you to store images on the camera for several weeks, regardless of the image size or transfer rate," explains Bayoumi.

Usually, cameras only supply the images, while processing and recording take place later on a central PC using video management software. However, with the decentralized MOBOTIX concept, a high-speed processor and, if requested, a digital long-term flash memory (MicroSD card) are built into every camera. The PC now serves purely for viewing and controlling the camera, but not for analysis or recording. The benefits: The system requires less network bandwidth since the cameras themselves process the data and do not send a constant feed of information to the computer for analysis. Plus, fewer cameras and recording devices are required.

|

| Ultrajaya will be installing 30 additional cameras in the production area over the course of 2013 |

Robust cameras for extreme conditions

Another important factor was the sturdiness of MOBOTIX cameras. Marvin Bayoumi comments: "The cameras are installed beneath cold and warm piping to monitor production in the cooking and ultra heat treatment areas. These pipes can emit a lot of steam at times. This means that the cameras have to be resistant to extreme conditions, with high temperatures and humidity levels." Because the camera housings are compliant with protection classes IP65 and IP66 and do not include any moving parts, they can withstand dust, dirt, water and heat.

What’s more, Ultrajaya can save costs thanks to the MOBOTIX system. There are no license or upgrade fees required for the proprietary MxControlCenter software, which can be connected to an unlimited number of cameras for centralised evaluation. MOBOTIX supply the video management software for free. And since the cameras can be supplied with power via the network cable (Power-over-Ethernet, or PoE), the company was able to lower its costs for wiring its buildings. "We can pass on important information or security warnings via Voice-over-IP using the camera’s data cable. This is why we have combined some of the cameras with external loudspeakers and amplifiers," says Bayoumi. Some cameras are also connected to manual fire alarms for use in emergencies. If an employee presses this button in an emergency, his location will be displayed in MxControlCenter.

Four project phases

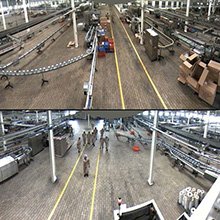

Ultrajaya is currently operating a total of 60 MOBOTIX cameras. The cameras were installed between the end of 2007 and the end of 2012 in four project phases: The first phase of the project was focused on monitoring the production zone, starting with the warehouse for raw materials, cooking (ultra-heat treatment), filling, delivery of fresh milk, including the product packaging stage. Ultrajaya used the M24M Allround model for this area.

The company opted for the weatherproof Q24 camera with 360-degree panorama view for the cooking area, where high temperatures and humidity levels prevail. The latter was also put to use in securing the outdoor area. The M12D model functions as the day/night camera for monitoring poorly lit areas of the building and premises.

In the second phase of the project, Ultrajaya secured the construction site of the new production facility to prevent thefts. D14 cameras are installed alongside the Q24M. The cameras were linked to the control center via a fibre-optic cable, which guarantees reliable data transfer.

The third phase focused on preventing theft and sabotage of products and goods in the high-risk areas of the company.

In the fourth phase, Ultrajaya upgraded the security of their outdoor areas in order to better capture the forklifts, the incoming and outgoing trucks and vehicles, and even the faces of the people moving around the premises. "The detailed resolution enables us to recognise people and license plates on vehicles to a high degree of accuracy," Bayoumi points out.

Security across the whole premises

Now the entire company, both indoors and outdoors, is protected by MOBOTIX cameras. "This means we can maintain security across the whole premises and quickly get to the bottom of thefts. The cameras have already proved themselves, particularly under the extreme conditions that occur during the ultra-heat treatment of milk," Bayoumi concludes Ultrajaya will be installing 30 additional cameras in the production area over the course of 2013 to be able to capture images with more precise details, such as the number of product labels.