Video surveillance systems can be used in a variety of ways within the mining industry |

Challenges associated with the application of surveillance systems in mining plants

Besides perimeter security, precious metal / stone mines normally have hundreds of CCTV cameras installed throughout the plant. These surveillance cameras observe the many processes within the plant and are mostly installed in a permanent, overt manner, with portable covert cameras being used on a temporary basis. The control room operators observe the general movement of plant and people, but invariably with limited success. Without the ability to effectively highlight unusual or high-risk events, video surveillance operators have too many security cameras to monitor and cannot effectively detect the tell-tale events that could betray suspicious activities.

Mature intelligent video management systems that are now available can provide strategic assistance |

However, the mature intelligent video management systems that are now available can provide strategic assistance and integrate with virtually any source of event data. Complex rules can be constructed to take into account related, but disparate events, which indicate impending failure or situations that warrant further investigation. These enable the video operator's attention to be targeted much more effectively to potentially productive areas.

Exploiting the functions offered by existing integrated video security systems in other environments

Nowadays any well-developed business administration system uses many tools to achieve business goals. Some industries have highly sophisticated systems which integrate video analysis and other data, allowing automated in-depth analysis to a degree impossible for humans within a workable timeframe. To reveal the potential for adopting and adapting similar systems for use in a mining environment we first need to look at systems already employed. One such example is the toll plaza, where a lot of money changes hands in what can be a very remote location.

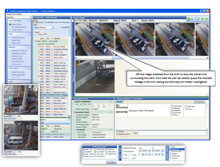

When this kind of technology is used for monitoring transactions at toll plazas, it can handle metadata including identity of operator, event inputs from axle-counting and other road-side devices, vehicle number plate recognition, transaction detail, video motion detection, date and time etc. For toll applications a rule-based data processing engine generates events for detected anomalies. The system extracts off-line images for each of these events, while a powerful easy-to-use query tool allows the user to drill down to the relevant exceptions. This enables management to view each anomaly rapidly, and either, after auditing the event, close it off for higher management check-up, or print it via a customised and automated report writer. In the latter case an operator disciplinary investigation is possible. And being linked directly to the DVR or NVR system means the recordings can be reviewed immediately. Without this kind of rapid event viewing system, verification is a laborious or virtually impossible task, and users seldom verify events that take place.

View larger image As at toll plazas, using an intelligent surveillance solution to monitor transactions could increase the level of information captured |

In the ideal intelligent electronic security system all the events captured in the sub systems would be critically analysed in a proper trend analysis. This would not only extract relevant process control data, but more specifically, the security risks. For example, the emergency stoppage of a conveyor belt might be an orchestrated event to create an environment in which the mined product can be removed by hand during the resultant spillage recovery operation.

Risk assessments using trend analysis

Currently in such situations consideration is rarely given to which operators and security staff are on duty in the plant at the time. A well-defined trend analysis could quite conceivably extract the fact that it is always the same staff on duty when this transpires. To analyse this trend on a manual basis is nigh impossible. Obviously the risk associated with this particular exception varies depending on the mining environment, as the concentration of the mined product may be so low that the risk is minimal. However, it may play a role within the context of the bigger picture.

A customised video security system that is integrated with other control and management systems can provide many mining operations with a very powerful tool |

The first weight measurements mentioned above are seldom compared against the measurement of the final product. The extended time factor from the start to finish of processing usually makes manual checking impractical. However, many sophisticated systems can be installed along this process and valuable events may be extracted from these systems to capture and highlight a trend in an exception reporting format. It is quite conceivable that a trend analysis would pinpoint a problem long before the end of the ore processing time has been reached.

Key benefits of an integrated surveillance solution

Clearly any system helps security staff concentrate on more fruitful activities increases efficiency and improves security. But the availability of a customised video security system which is integrated with other control and management systems can provide many mining operations with a very powerful tool which can deliver significant benefits in other areas too, such as safety and processing efficiency for example. Once managers realise the power at their fingertips they see new opportunities for applying it and considerable added value can be derived from the investment.

Points to consider when choosing an intelligent security system

|

| No off-the-shelf product will be a perfect fit, a considerable amount of customisation is involved |

You will need to confirm that all your currently installed systems can be interfaced to enable the necessary event extraction by external software controlled systems, and that software development kits (SDKs) and application programming interfaces (APIs) are available to facilitate this. If they are not, then your software integrator must be able to extract the data by other means. He too needs to be selected for the appropriateness of his skills and track record.

Alongside supplier representatives, the project team should include someone to represent you, the end-user. This person's role is to provide the input to enable the definition and creation of a rules base which will then form the basis of the analysis through a filter process, so he needs to have an intimate knowledge of plant processes.

Any potential purchaser needs to realise that the system will need to be fine-tuned during use as everyone on the team will find methods of improving the system performance and because of this, on-going software maintenance will form part of the complete solution.

|  |  |

| Jan de Beer MultiVid | Johan Raubenheimer Fourier Systems | Carmen Lahr Geutebruck GmbH |